Behind the scenes: Keeping workers safe – a global challenge

29th Apr 2024 | Leave a comment | By Jacob Kazungu

The International Labour Organisation (ILO) estimates that almost three million people die each year as a consequence of workplace-linked disease or injury, with a further 395 million workers sustaining a non-fatal workplace injury.[i] Families and dependants can be impacted by the loss of a main household income during a period of recovery or, in the case of permanent disability or death, in the longer-term.

In the geographies in which PIDG works – sub-Saharan Africa, south and southeast Asia – we see some of the worst statistics for workplace fatalities in the world.[ii]

As well as being a tragedy for individuals, such devastating losses have an impact across society and wider economies, potentially undermining gains made towards delivering on the UN Sustainable Development Goals.

Robust Health, Safety, Environmental and Social (HSES) management systems are central to the work of PIDG and its companies, and we have a dedicated global Impact team focused on keeping people safe across our growing portfolio. We are determined to ensure that everyone goes home safely, every time.

Case study: East Africa Marine Transport

To demonstrate our wider approach, I will focus here on a project which has been a huge part of my working life since I joined InfraCo Africa and the PIDG Impact team. The East Africa Marine Transport project will soon commence commercial operations as Lake Victoria’s first, scheduled, roll-on / roll-off freight vessel. Opening up vital trade links between Uganda and Tanzania, with potential to expand into Kenya in the future, EAMT will drive down transport emissions by cutting journey times and taking freight vehicles off the road.

On paper, EAMT is perhaps the riskiest of InfraCo Africa’s current projects, and construction of the 1,000 tonne, 96-metre-long vessel has presented some significant HSES challenges, flagging activity for eleven of the twelve PIDG Lifesaving Rules. However, the project has an exemplary HSES record to date, and I would like to share with you how this has been achieved, and will continue to be maintained, as the vessel enters operations.

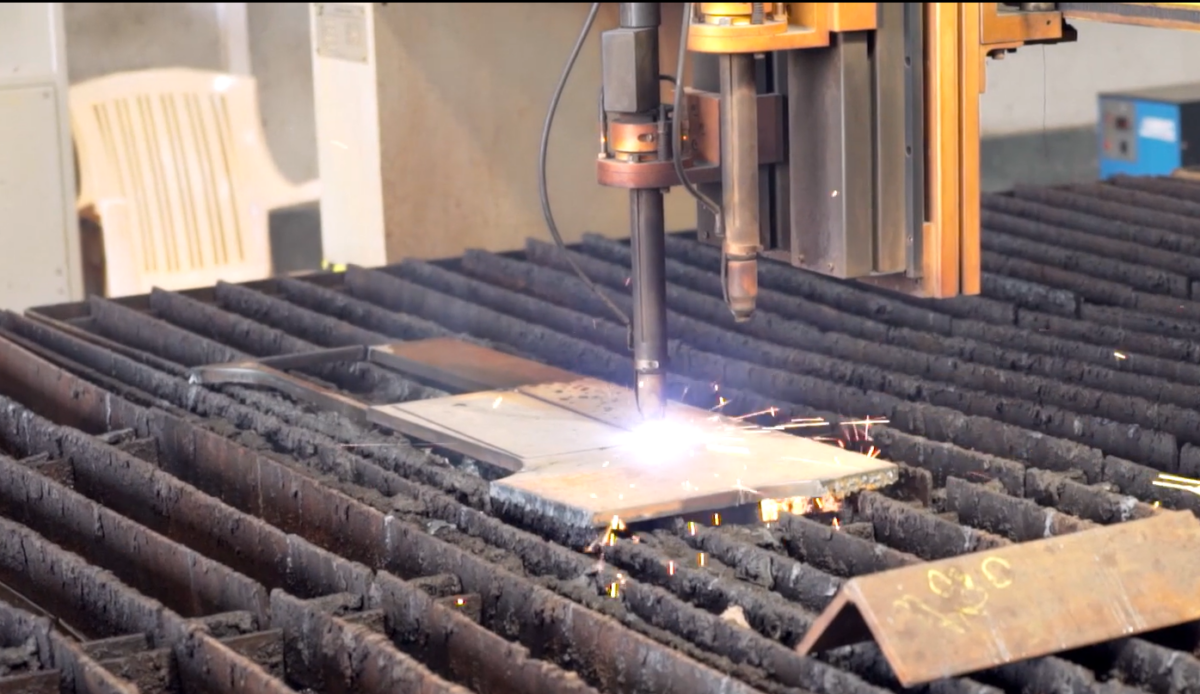

Shipbuilding on this scale represents a new industry in Uganda. Drawing on its own experience and the expertise of EAMT’s stakeholders – PIDG, InfraCo Africa, OSK Design, S&O Maritime, and Grindrod – the EPC contractor, SECO Marine (U) Ltd, (an Alpha Group company), undertook extensive capacity-building work to train local staff through mentorship and training around safe working practices. They also ensured that any specialist contractors brought in to undertake tasks such as sandblasting adhered to the Environmental and Social Management System (ESMS) which was upgraded at the start of the project to meet PIDG requirements, giving investors comfort that appropriate governance processes were in place to manage project risks.

So what were the risks?

As you can imagine, building a vast vessel and purpose-built shipyard on the shores of Lake Victoria involved multiple contractors and individuals. At its peak, the project created 140 construction jobs.

Although by no means exhaustive, some key risks and mitigations we identified were:

What role did the PIDG Impact team play?

Site safety hinges on training, and on the development of a strong safety culture. From the outset, EAMT implemented the PIDG Lifesaving Rules, and these were integrated into the contractor’s HSES processes. We also provided training to support the contractor to operationalise the rules which they reinforced through daily, task-focused tool talks designed to ensure that workers were fully aware of specific risks and were empowered to stop work if they identified any safety concerns.

Throughout the construction process, members of the PIDG Impact team visited the shipyard in Entebbe Uganda, to support the shipbuilding contractor in implementing the agreed HSES management system. The East African team tapped into the expertise of HSES colleagues from our London, Casablanca, and Singapore teams during the construction phase, as well as for the vessel launch.

Our role also involved HSES capacity building. SECO’s HSES manager attended a PIDG institute knowledge-sharing platform in Nairobi, enabling them to learn from others working across PIDG portfolio projects and businesses, to gain peer-support and to upgrade their relevant HSES skills.

The PIDG Impact team undertook joint management site walks with the shipbuilding contractor to spot hazards, identifying pragmatic corrective and preventative actions in a collaborative environment. The project team also held regular meetings with the contractor, and HSES was included as a standing agenda item for discussion, further reinforcing PIDG’s position on the value of HSES in its investments.

Finally, we conducted visits designed to evaluate the general HSES governance of the shipbuilder’s ESMS. These reports were instrumental in the identification of good practice as well as opportunities for improvement. Ahead of the launch, I stayed on site for ten days, working with the team to ensure a safe and successful vessel launch.

Climate change and HSES

This year, the ILO is highlighting the impacts of climate change for occupational health and safety. This is an increasingly urgent topic for HSES professionals globally, as we seek to keep workers safe in the face of rising temperatures and climate-induced floods, storms, and wildfires.

At PIDG, all of our projects are Paris-aligned to mitigate future climate change and we undertake thorough project screening to identify climate risks to people and to our infrastructure assets. Our projects are required to have Emergency Response Plans (ERPs) that include climate-related risks. Implementing robust reporting procedures that specifically record climate hazards also enables us to raise awareness of these emerging risks across the wider PIDG portfolio.

This is not an abstract concern. In East Africa, we are experiencing the impact of the ongoing El Niño event and construction timelines for EAMT have been impacted by unseasonal rainfall in Uganda. In 2023, rising water levels impacted the operations of our other marine transport businesses on Lake Victoria, Kalangala Infrastructure Services (KIS) and Waterbus. For both businesses, rising water levels led to the submerging of vessel landing sites, posing not only a threat to vessel operations, but also impacting the safety of passengers and crew. Waterbus has adapted to this risk by using alternative landing sites, and KIS has adjusted the docking position of its ferries to ensure uninterrupted services.

On the EAMT build, we have worked to mitigate potential slip, trip, and flooding hazards in wet weather – in some cases stopping work entirely. Weather extremes wrought by climate change also necessitate our putting systems in place to prevent workers’ experiencing heat stress, heat exhaustion and prolonged UV exposure.

Are we doing enough to keep people safe?

In HSES, the key is constant vigilance. Whilst we are seeing promising reductions in HSES incidents linked, for example, to electrical safety, we cannot be complacent. PIDG operates in difficult markets where legal frameworks and safety knowledge are not advanced and, as I have discussed, there are emerging risks linked with climate change which we need to keep abreast of to mitigate their potential impact.

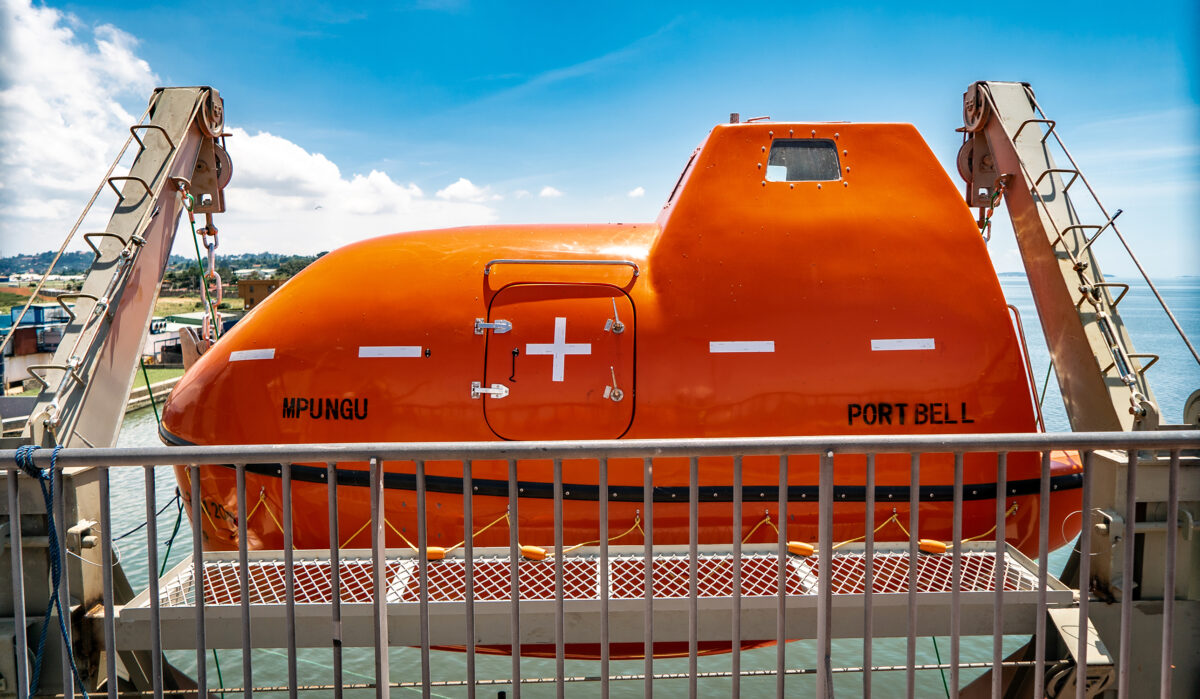

At EAMT, we have done a climate risk assessment and are aware of the potential risks posed by climate change to the project. We will manage these by requiring the project to include these considerations in their emergency response plan hence the team will be aware of the actions to take should they encounter, for example, high water levels. Other issues are high temperatures – the M.V. Mpungu has well-designed cabins for crew and shaded areas for passengers which will protect them from exposure to high outdoor temperatures and weather elements during voyages. We are also aware of the risk of heat stress and make sure that the shipbuilder considers workers’ well-being – this is done though monitoring the working hours and provision of mechanical ventilation using fans and ducts including window fans to bring in fresh air from outside into working areas.

Where do we go from here?

The timeline of the ILO’s Global Strategy on Occupational Safety and Health for 2024-2030 is concurrent with efforts to achieve UN SDG 8, ‘Decent work and economic growth for all.’ This is, I believe, no coincidence. Without addressing workplace health and safety, it will be impossible to achieve this and many other SDGs.

With a growing portfolio of projects reaching construction and operations across the group, working as a coherent PIDG Impact team is key as it enables us to draw on a wealth of experience and lessons learned across multiple sectors, geographies, and specialisms – as we did for EAMT – and this has tangible benefits for safety on our projects. The Impact team also includes colleagues from Sustainable Development Impact (SDI) as the two disciplines are intertwined, our projects cannot deliver SDI if people are not safe, or their workers’ rights are not upheld.

On EAMT, we are not complacent.

The safety of the vessel’s design and construction have been monitored throughout and the vessel has been classed by international certification company, Bureau Veritas. The project will commence commercial operations later this year, upholding key international standards around security of shipping, the International Convention for the Prevention of Pollution from Ships (MARPOL) and in compliance with International Maritime Organisation (IMO) standards for Safety of Life at Sea (SOLAS). To maintain its strong safety record, the M.V. Mpungu will be operated by experienced vessel operator, Grindrod, and will deploy a vessel management system based on the International Safety Management Code (ISM code), the system will also be informed by the ESMS which is aligned with PIDG requirements. With support from EAMT and its stakeholders, the vessel crew has been trained and mentored by experienced vessel operators across East Africa, a well-trained crew will be key to the vessel’s safe operations.

Through our engagements, the PIDG Impact team has contributed to the creation of safety awareness within the wider Ugandan shipbuilding industry and SECO has set a standard in safety management that other shipbuilding facilities can emulate, both in Uganda and across the wider region.

I would like to leave you with the thought that, as a result of our collective efforts, all 140 construction workers on the EAMT build, and the various contractors engaged by the shipbuilder, leave this project with a better understanding of workplace health and safety. Crucially, these individuals have adopted a safety culture; feeling able to speak up if something doesn’t feel safe. It is this awareness and empowerment that will ultimately save lives.

If you wish to find out more about the work, we are doing to keep people safe, you can find further insights and download key documents here. If you have any concerns about health and safety on one of our projects, you can find details of how to report it on our ‘Report A Concern’ page here.

[i] Occupational safety and health: Nearly 3 million people die of work-related accidents and diseases (ilo.org)

[ii] ILO, “ILO Global Estimates of Occupational Accidents and Work-related Illnesses” [based on Jukka Takala, Päivi Hämäläinen, Riitta Sauni, Clas-Håkan Nygård, Diana Gagliardi, Subas Neupane, “Global, Regional and Country level Estimates of the Work-related Burden of Diseases and Accidents in 2019” accepted in the Scandinavian Journal of Work, Environment & Health], forthcoming. (Accessed via ‘A call for safer and healthier working environments document.’ wcms_903140.pdf (ilo.org))

Leave a Reply

Related projects

Tanzania / Uganda: East Africa Marine Transport

Facilitating regional trade